Risks and challenges

Importance of humidity control in meat processing:

- Impact on product quality and food safety

- Overview of industry standards and practices

- Connection between precise humidity control and operational efficiency

Points to Cover:

- Role of humidity in maintaining meat freshness

- Consequences of improper humidity levels

- Link between humidity and spoilage

- Benefits of controlling excess moisture

With uncontrolled humidity you risk:

- Risk #1

- Risk #2

- Risk #3

- Risk #4

“We wanted a simple technical solution, which would work well with our refrigerating system and be energy-efficient,” says Bourhis. “We visited the sites of two other companies in our field, who had already installed Munters equipment. They had completely solved their frost problems in the cold rooms and eliminated water droplets on the ceiling of the carving rooms. That made our minds up for us, we did the same thing and it was a success.”

Oliver Bourhis, Factory manager

Essarts poultry plant

Meat dehumidification

Meat Processing and Moisture Control:

- Common moisture issues in meat facilities

- Effects of condensation on food safety

- Implementing effective dehumidification strategies

Points to Cover:

- Identification of critical areas in meat processing facilities

- Factors contributing to condensation in processing rooms

- Design and implementation of dry tools and equipment

- Importance of maintaining hygiene standards with dehumidification

Poultry processing

Importance of poultry processing dehumidification

- Challenges posed by excess moisture in poultry processing

- Benefits of effective humidity control

Points to Cover:

- How dehumidification enhances product quality

- Impact on food safety and hygiene standards

- Relation to operational efficiency

- Contribution to extended shelf life

Pork & Swine processing

Swine Processing

Role of Moisture Control: Prevents condensation on surfaces, reducing contamination risk.

Quality Impact:

- Maintains meat texture and color.

- Hygiene Standards: Essential for compliance with food safety regulations.

Chicken processing

Chicken Processing

Challenges: High moisture from chilling and washing stages.

Dehumidification Role:

- Prevents bacterial growth.

- Improves drying efficiency before packaging.

Sausage processing

Sausage Processing

- Dry & Fermented Sausages: Require controlled RH for proper fermentation and drying.

- Texture & Flavor: RH influences protein binding and fat distribution, impacting mouthfeel and taste.

Challenges: - Maintaining stable RH during long curing cycles; fluctuations can cause cracking or uneven drying.

- Food Safety: Incorrect RH can lead to pathogenic growth during fermentation.Poultry Processing

Excess Moisture Issues: Leads to slippery floors, hygiene hazards, and microbial contamination.

Dehumidification Benefits:

- Improves product quality by reducing water retention.

- Enhances hygiene and reduces cross-contamination.

- Extends shelf life and supports operational efficiency

Optimal conditions for meat & poultry processing

Each meat category (fresh, smoked, cured, fermented) has unique RH requirements.

Most meat processing facilities follow HACCP and ISO standards also include GMB, which emphasize humidity control as part of environmental monitoring.

Recommended relative humidity (RH) varies by product type (e.g., fresh meat vs. cured products).

Optimal RH levels

- Fermented meat:

- Smoked:

- Curated:

- Fresh:

Requirements meat processing

The role of dehumidification within meat preservation techniques

Talk about how dehumidification can solve challenges within each technique and secure product quality and safety.

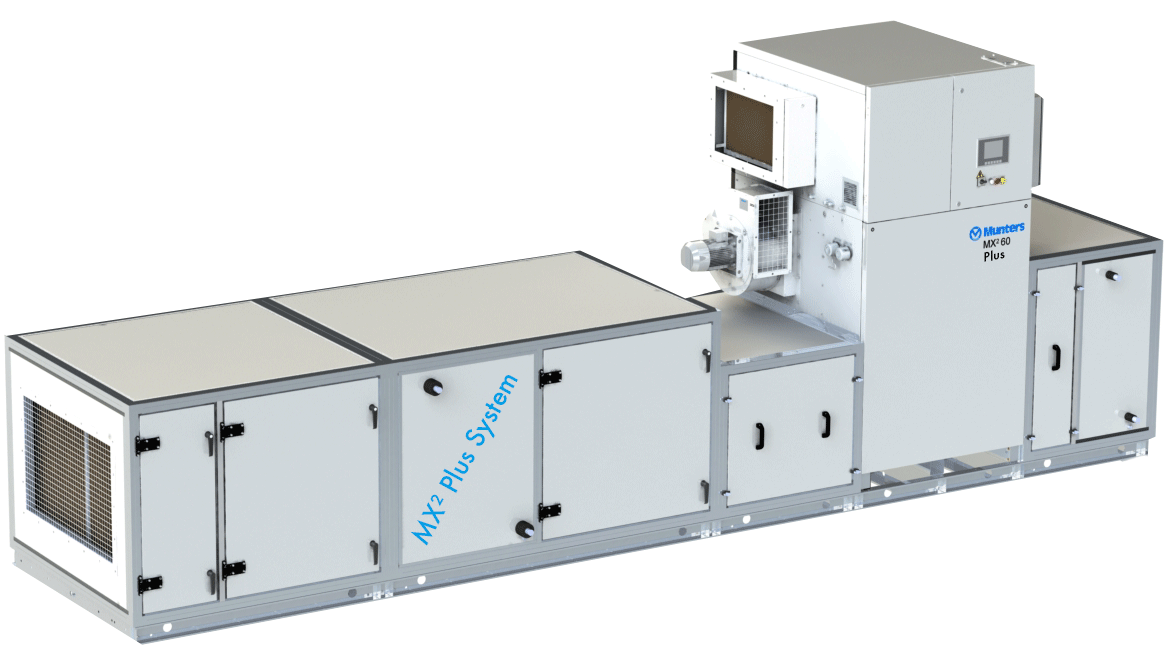

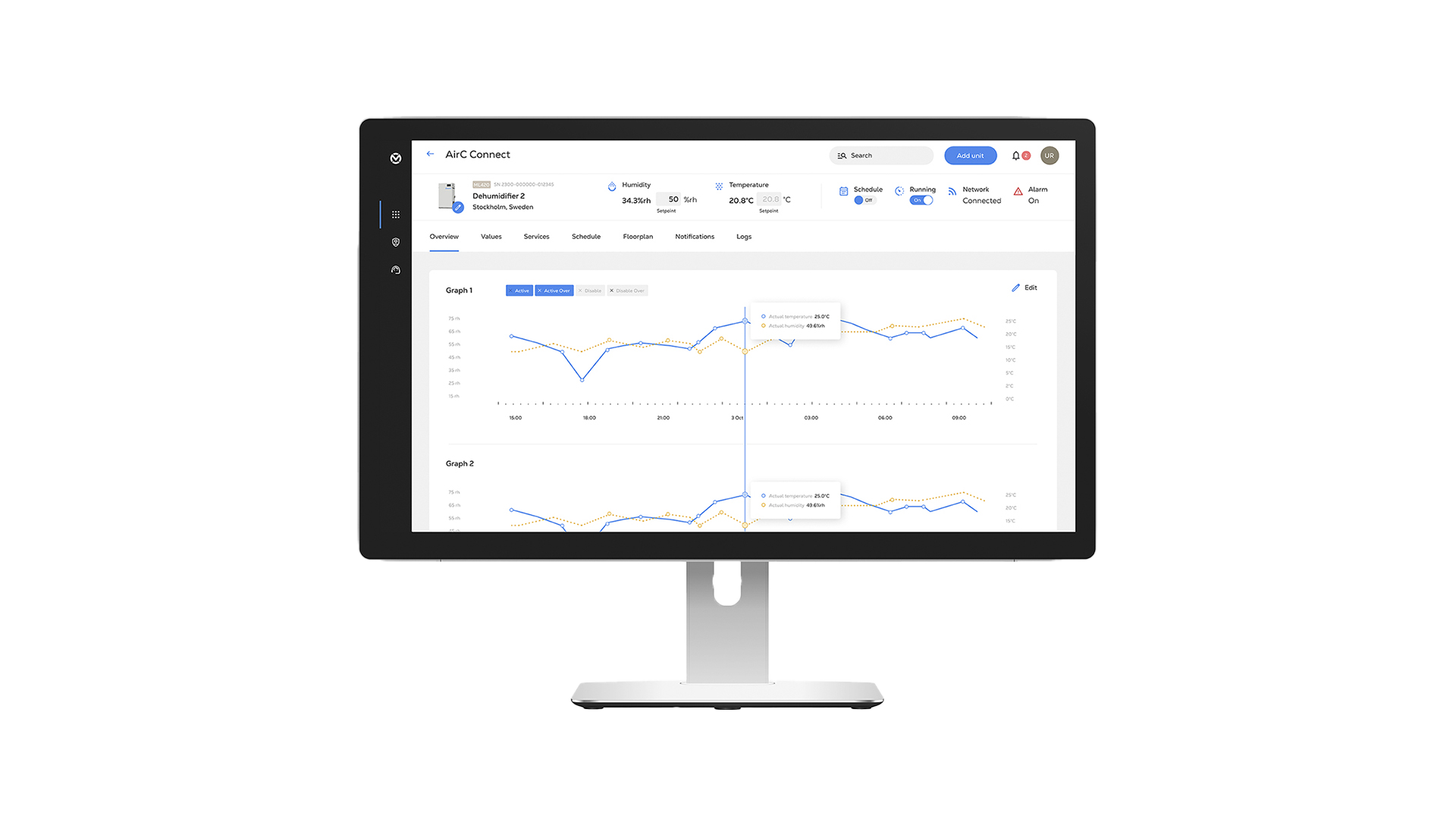

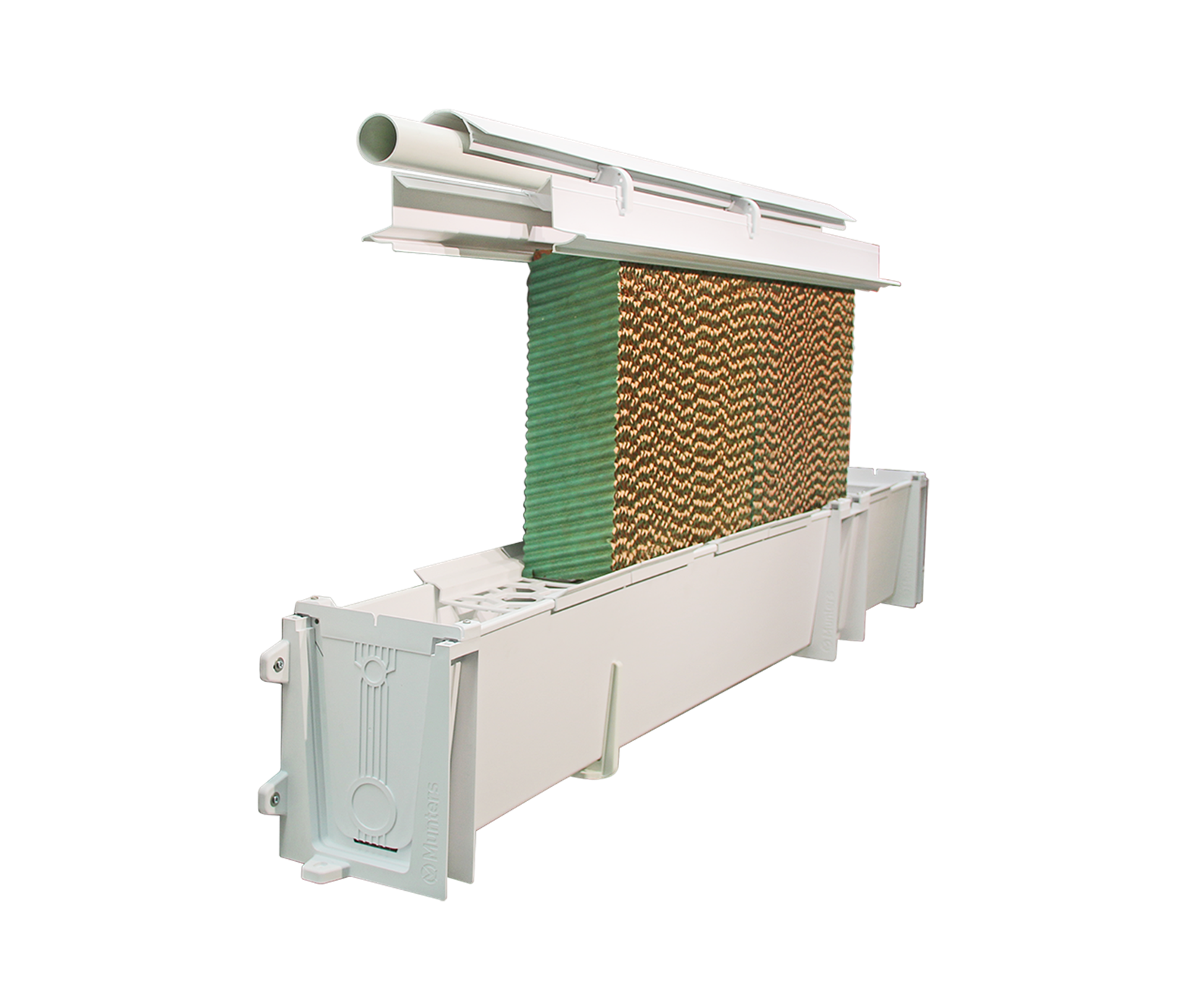

Featured meat processing dehumidifiers

Featured product 1

Featured product 2