Effective dehumidification is critical in pharmaceutical manufacturing

Pharmaceutical ingredients and products are often extremely hygroscopic and are easily damaged by excess moisture. Uncontrolled humidity in pharmaceutical production can also lead to dangerous mold and bacterial growth, contaminated or poor-quality product, and serious compliance issues.

The production of critical formulations in pharmaceutical and nutraceutical manufacturing requires precise humidity control and a perfect climate. This is because pharmaceutical, and laboratory environments, are extremely sensitive to ambient moisture. Exposure to moist air can cause products to deteriorate, stick together, soften, break apart, or become susceptible to microbial growth. Machines and pipes in silos and conveying lines may become clogged, impeding production, transport, and storage, as well as resulting in increased maintenance and product waste. Desiccant dehumidification can help prevent these costly, time-intensive problems.

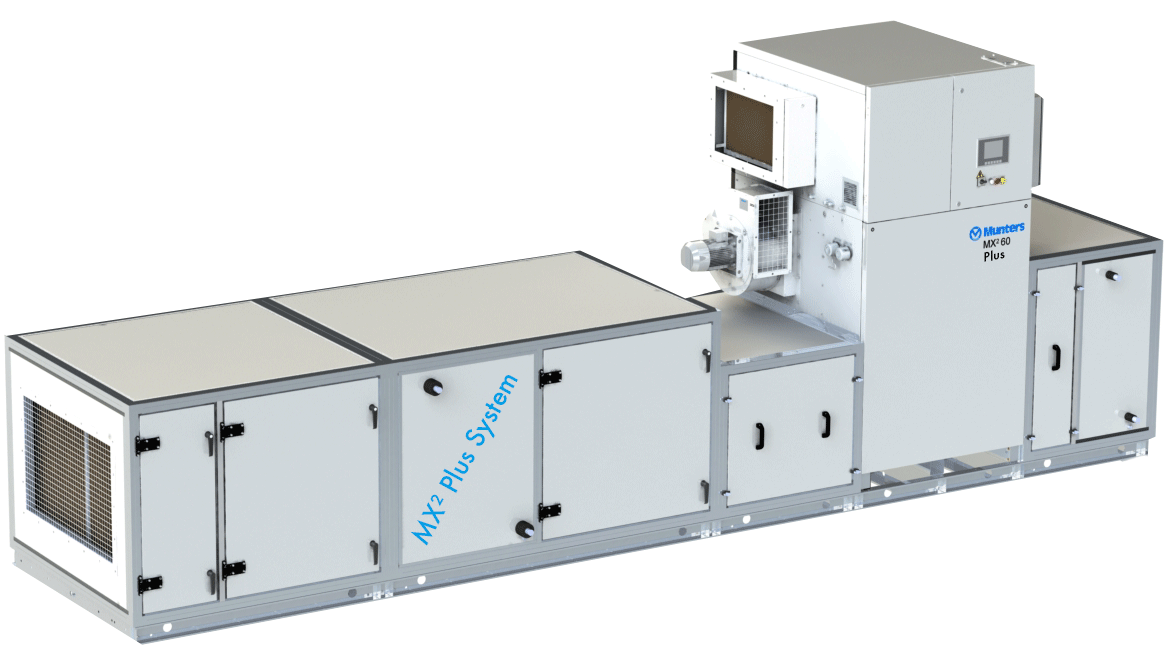

Munters has decades of experience in supplying desiccant dehumidifiers and climate control systems to the pharmaceutical industry. Our solutions are available for every area of pharmaceutical production, from small R&D labs to large clean rooms and commercial processing lines.

Key challenges

- Protect sensitive active pharmaceutical ingredients (API)

- Ensure product quality and safety

- Adhere to GMP and maintain regulatory compliance

- Avoid unexpected downtime

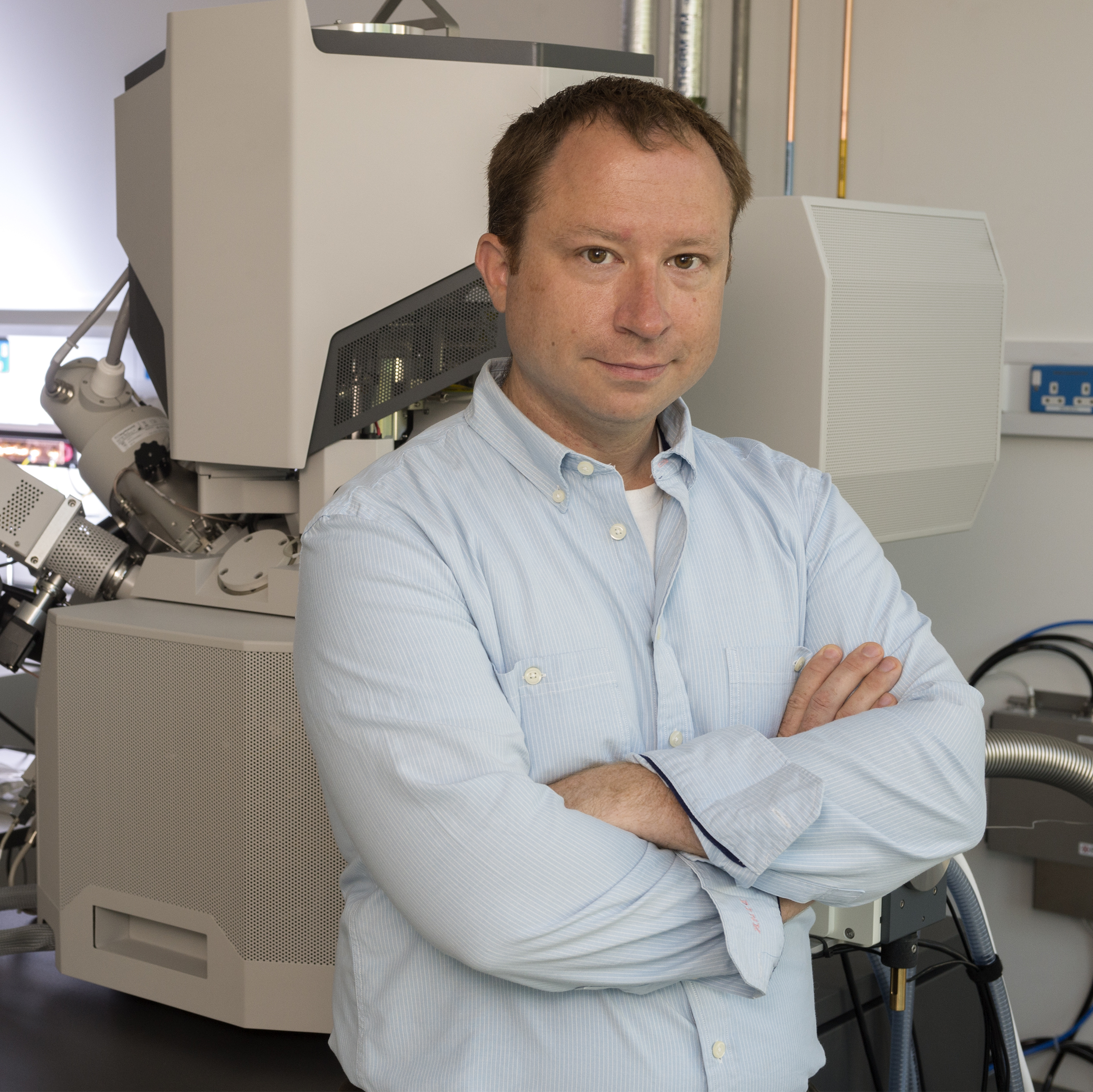

“Without dehumidification, even the slightest amount of excess moisture will cause ice to build on the specimens. This is a fundamental barrier to producing quality electron microscopic images. If the resolution is poor, we won’t get the image and won’t solve what we need to”.

Dr. Chris Russo, Laboratory of Molecular Biology

Medical Research Council

Why moisture control is critical in pharmaceutical processing

Without precise humidity control, every step of the pharmaceutical or nutraceutical manufacturing process can be negatively affected.

In a humid environment, raw materials will clump and stick during storage and conveying, resulting in product waste and excessive cleaning. Dosing and granulation during weighing, mixing, or blending, can be compromised due to ambient moisture.

In cleanrooms, laminar flow cabinets, and R&D labs, uncontrolled humidity can affect test result reproducibility, and will negatively impact the environment for the people working on the premises. In an environment with optimal and stable humidity, product drying times in fluid beds and coaters will be reduced, while the production output will increase in spray drying,

During filling and packing, humidity and moisture can harm product quallity, reduce shelf life, and in the worst case cause production stoppages. Excessive moisture in the cold chain creates frost, ice, and dangerous conditions for the workers.

Moisture is a hidden enemy in all parts of the pharmaceutical and nutraceutcial process, risking production efficiency, worker safety, and product quality.

Benefits of climate control

The most effective way to control moisture in your pharmaceutical manufacturing facility, laboratory, or clean room, is with a Munters desiccant dehumidifier.

Benefits of desiccant dehumidification:

- Year round, precise humidity and moisture control

- Maintain industry standards and regulatory compliance

- Maintain product efficacy and shelf life

- Reduce the risk of mold or bacteria growth

- Eliminate condensation

- Prevent ingredient or product clumping and sticking

Pharmaceutical manufacturing requires precise humidity control all year round to ensure critical formulations are manufactured in the perfect climate.

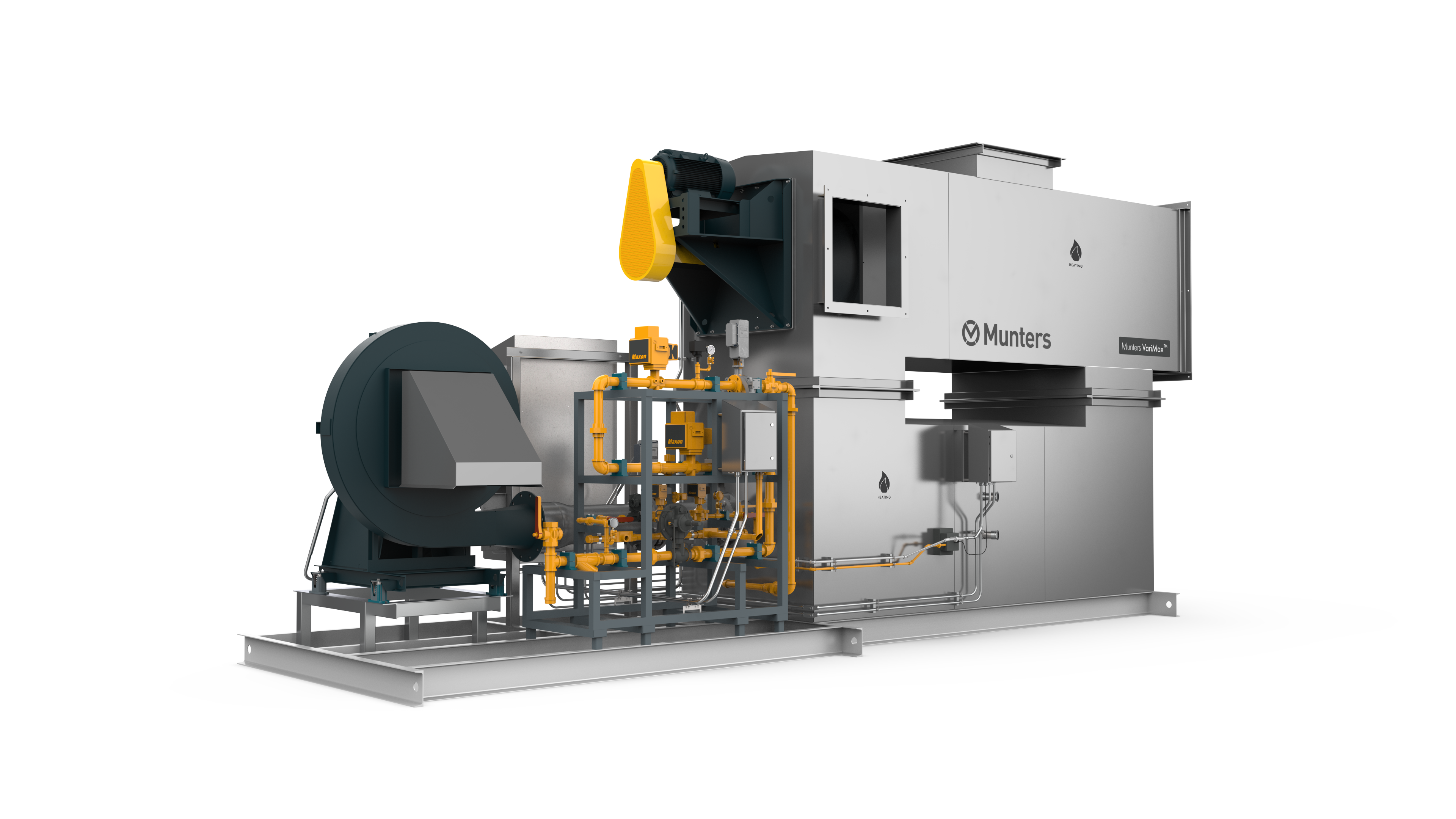

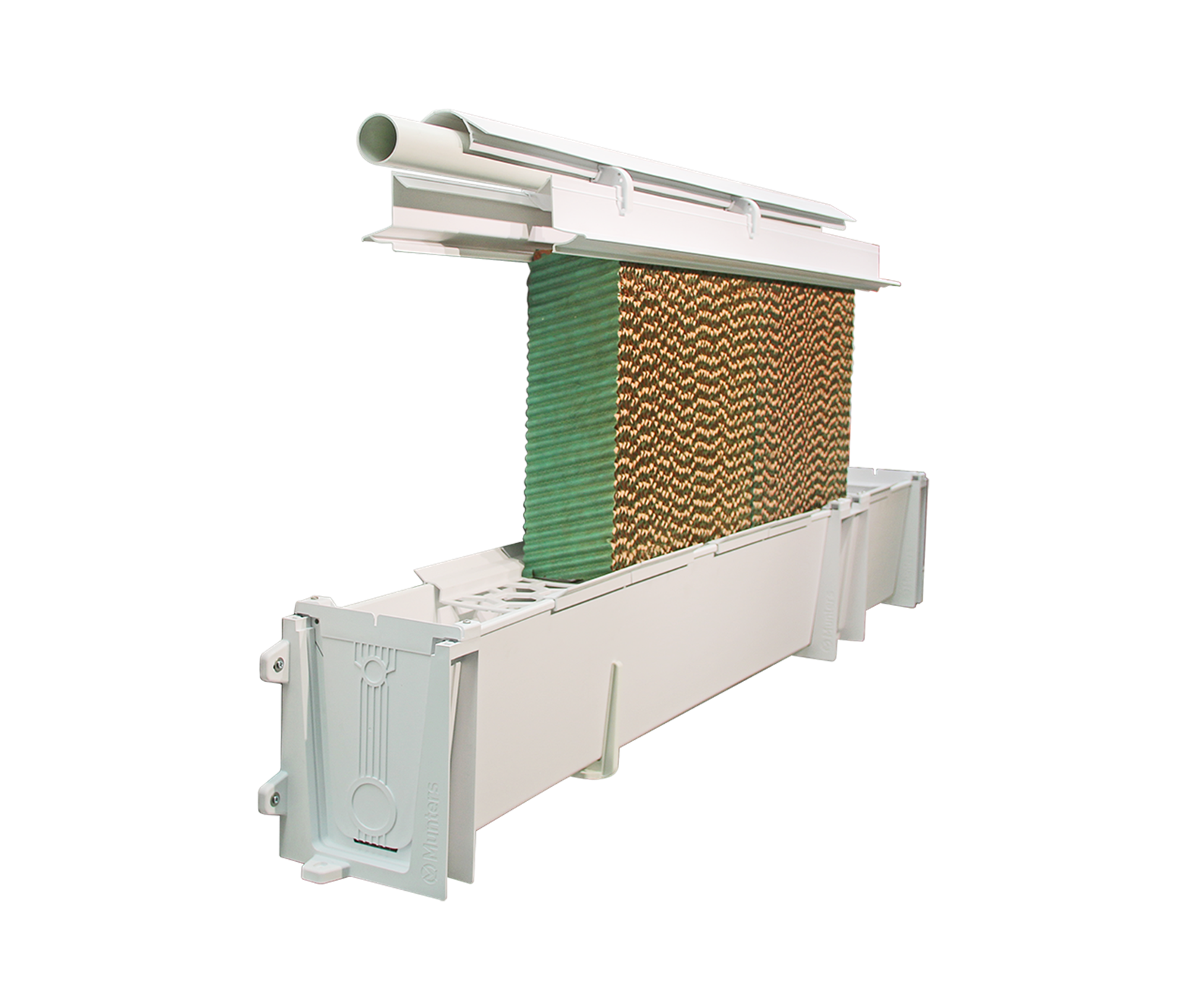

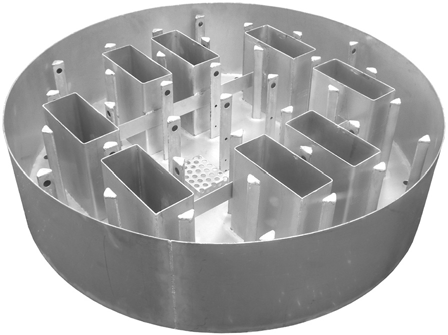

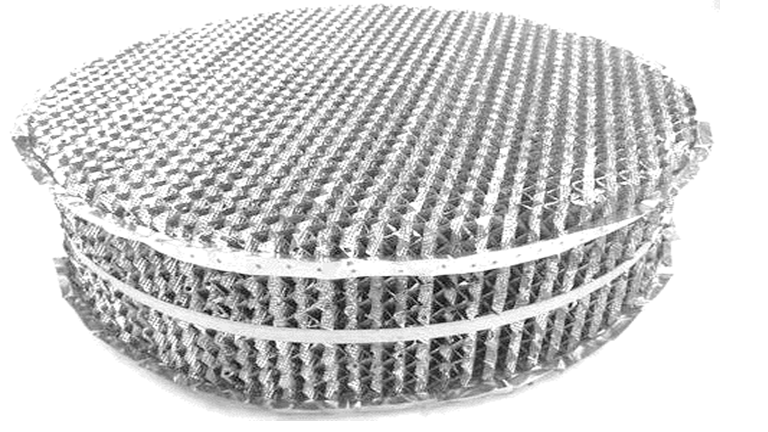

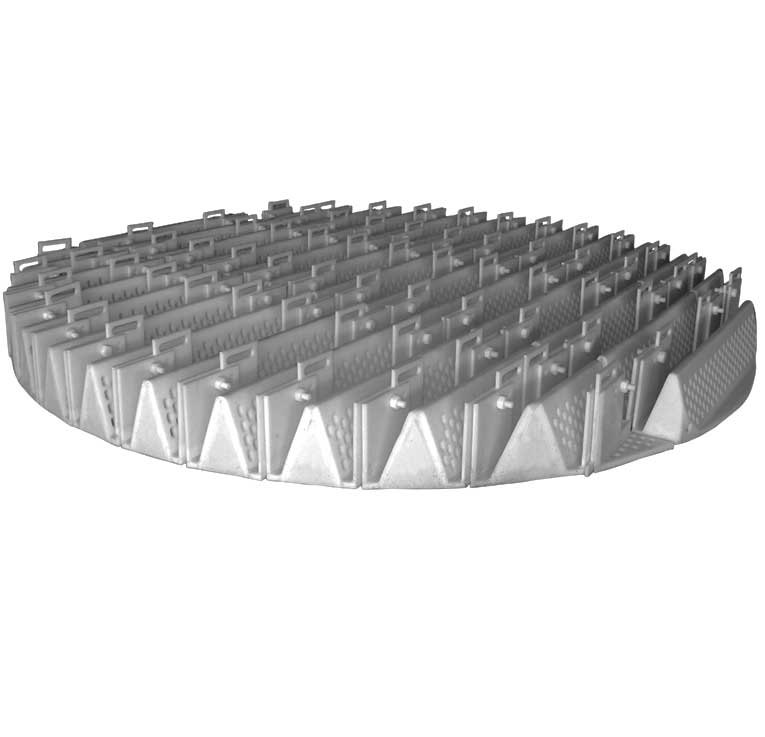

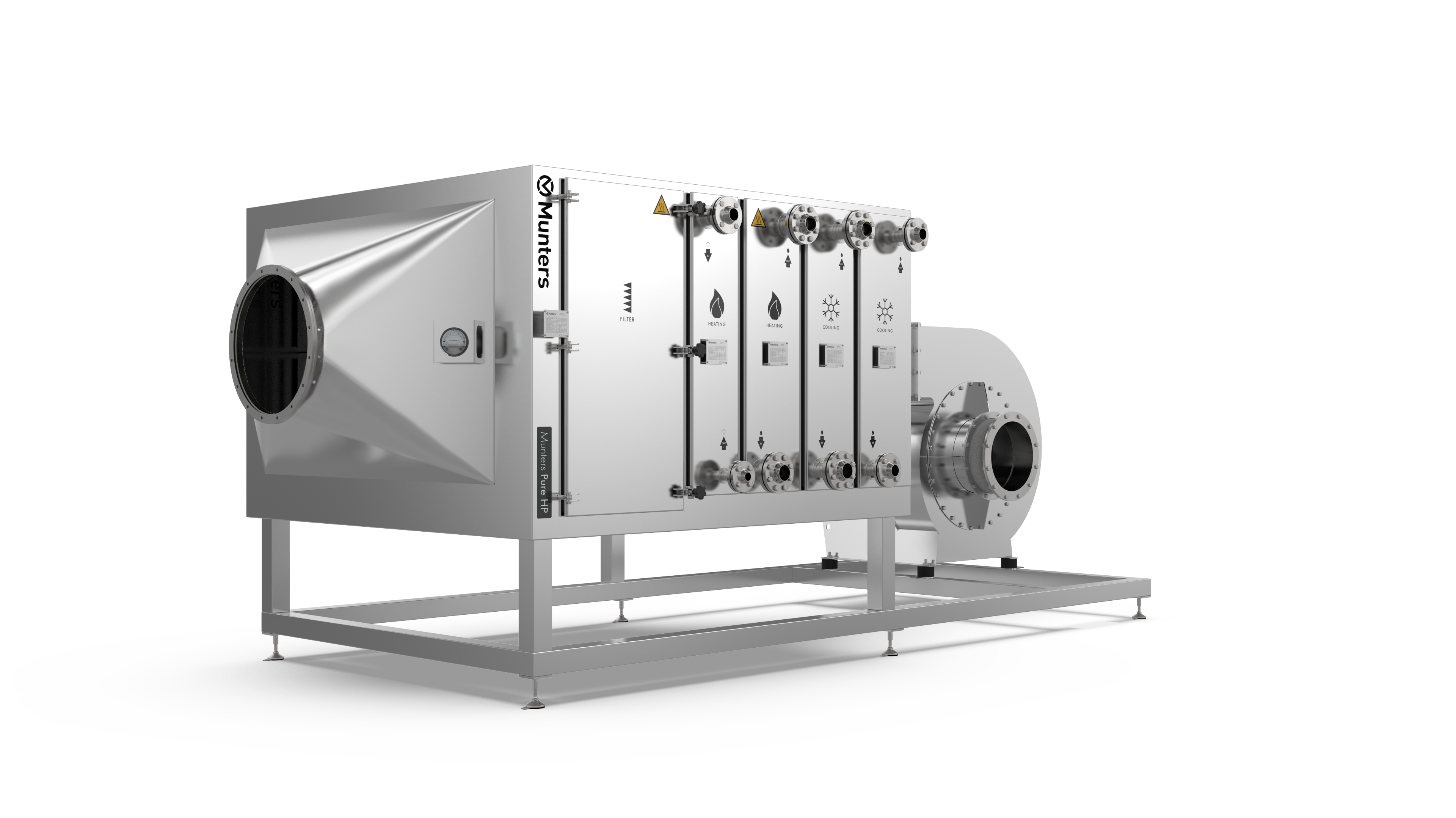

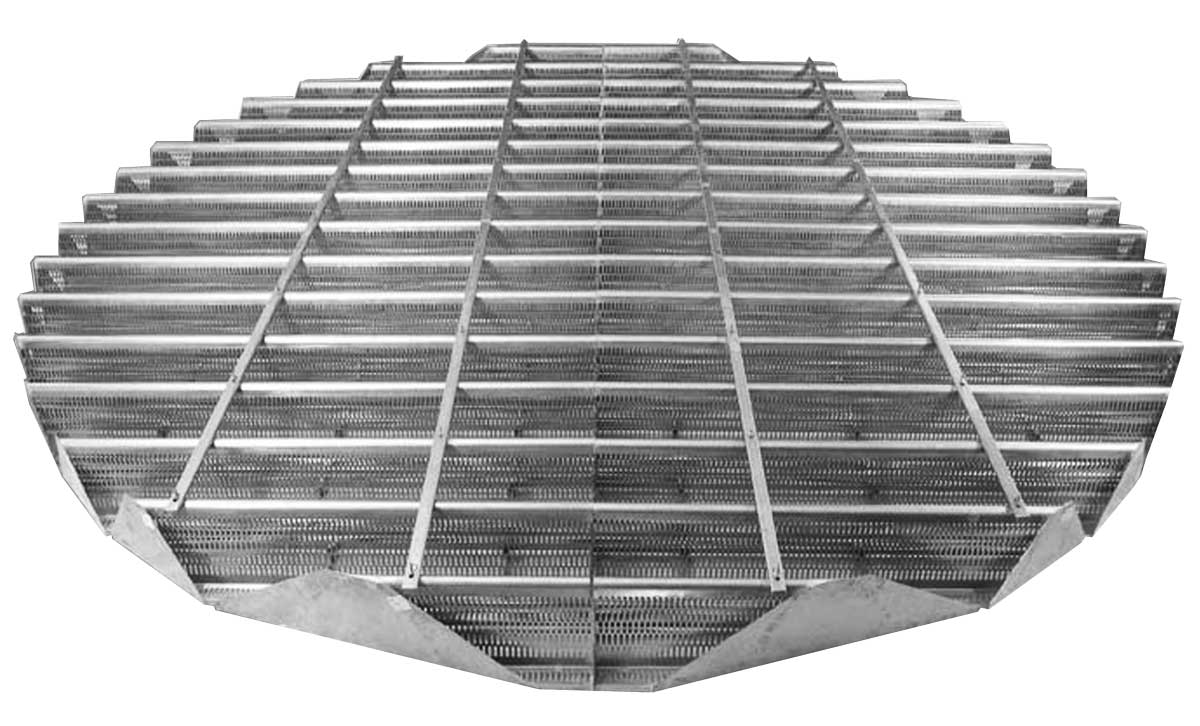

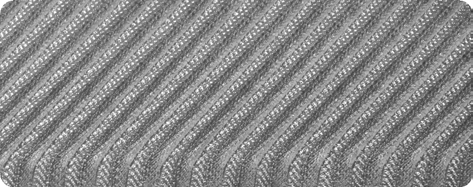

Secure your process and production targets with the Munters DSS Pro. A quality solution that provides stable, long-lasting performance, while still saving energy. When you need the air to remain at a precise humidity during production, the DSS Pro is the solution you can rely on.

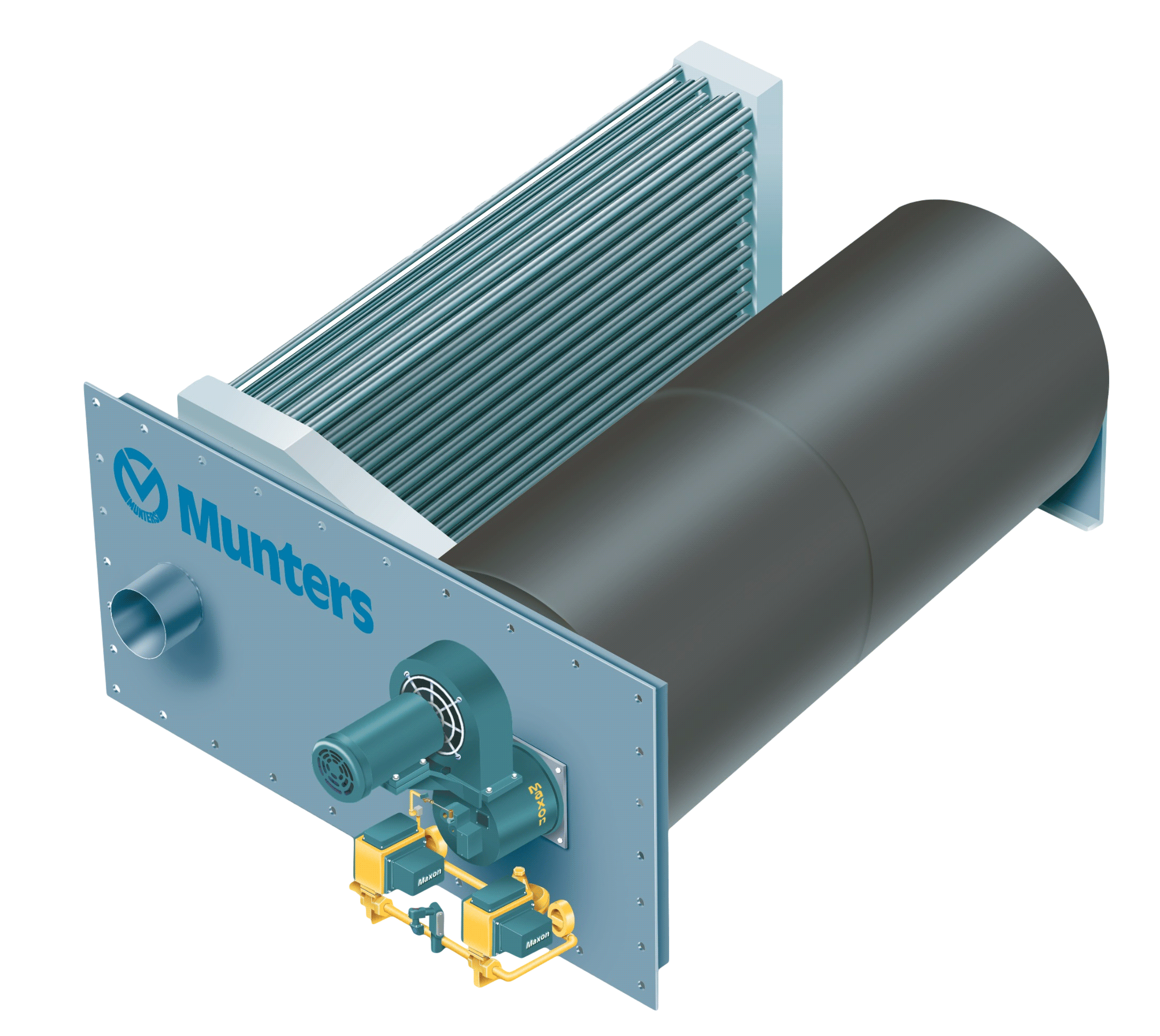

Do you use a cold store in your process? Without good climate control, your cold storage will develop condensation and a buildup of ice. State-of-the-art cold room dehumidification solutions prevent condensation before it turns into frost or ice, improving safety, product quality, and operational efficiency.

Discover Munters IceDry 1400 AirC. Safe, efficient, and proven in operation, it tackles humidity at its source. This stand-alone dehumidifier is designed specifically for cold storage and freezer facilities, and minimizes downtime as well as defrost or maintenance in your cold storage facility.

Diagnostics, cleanroom, or regulatory compliance - trust us, we're there

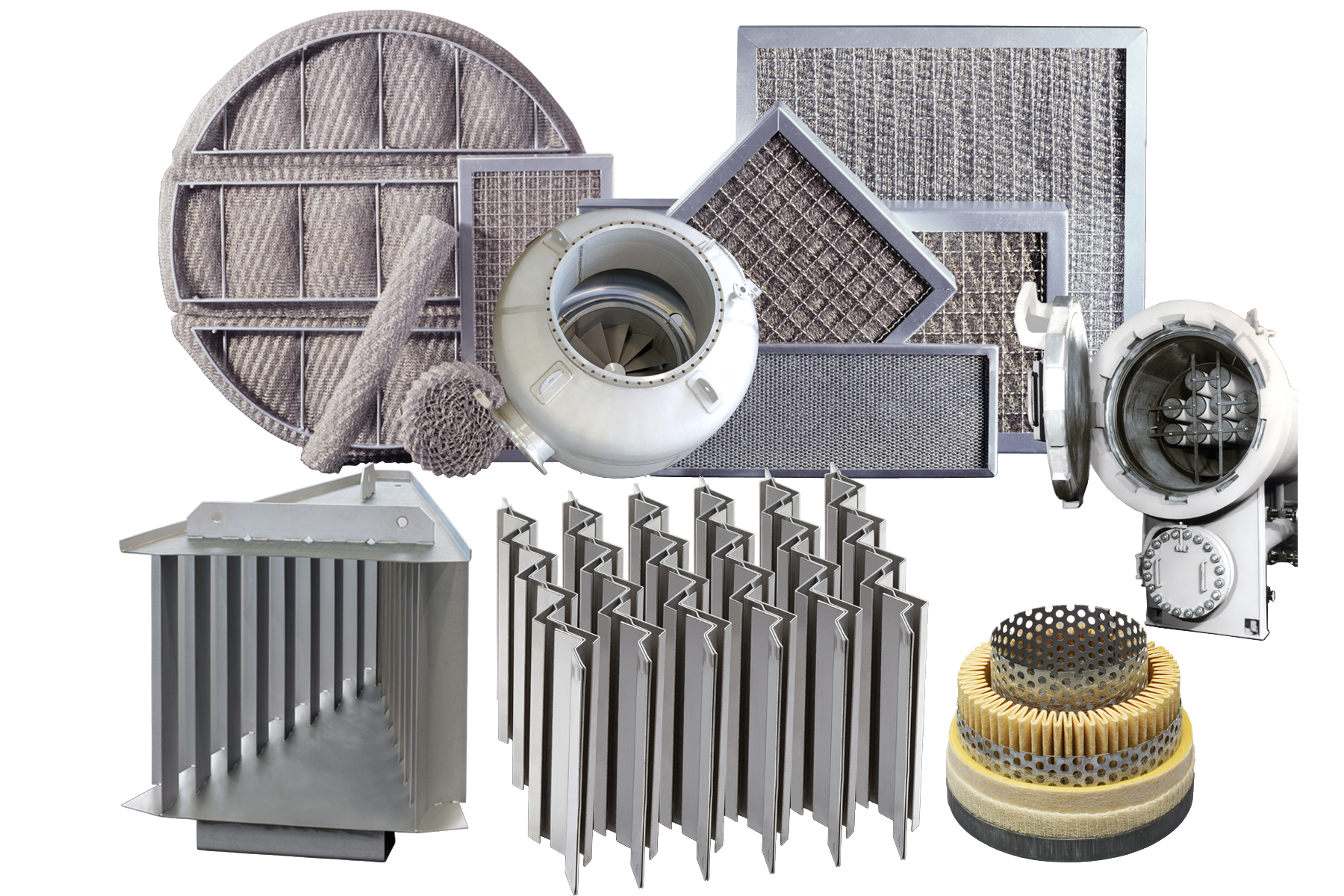

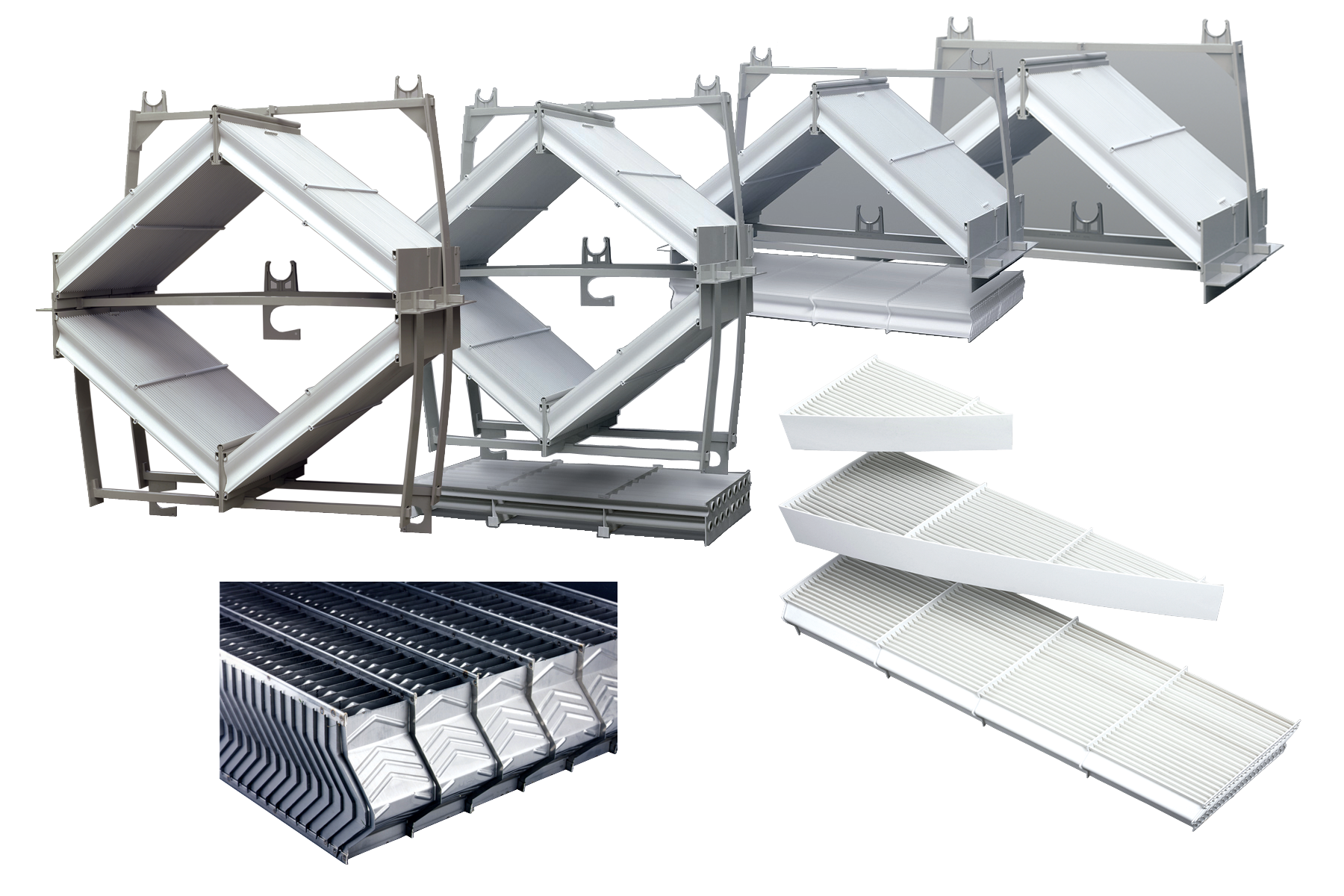

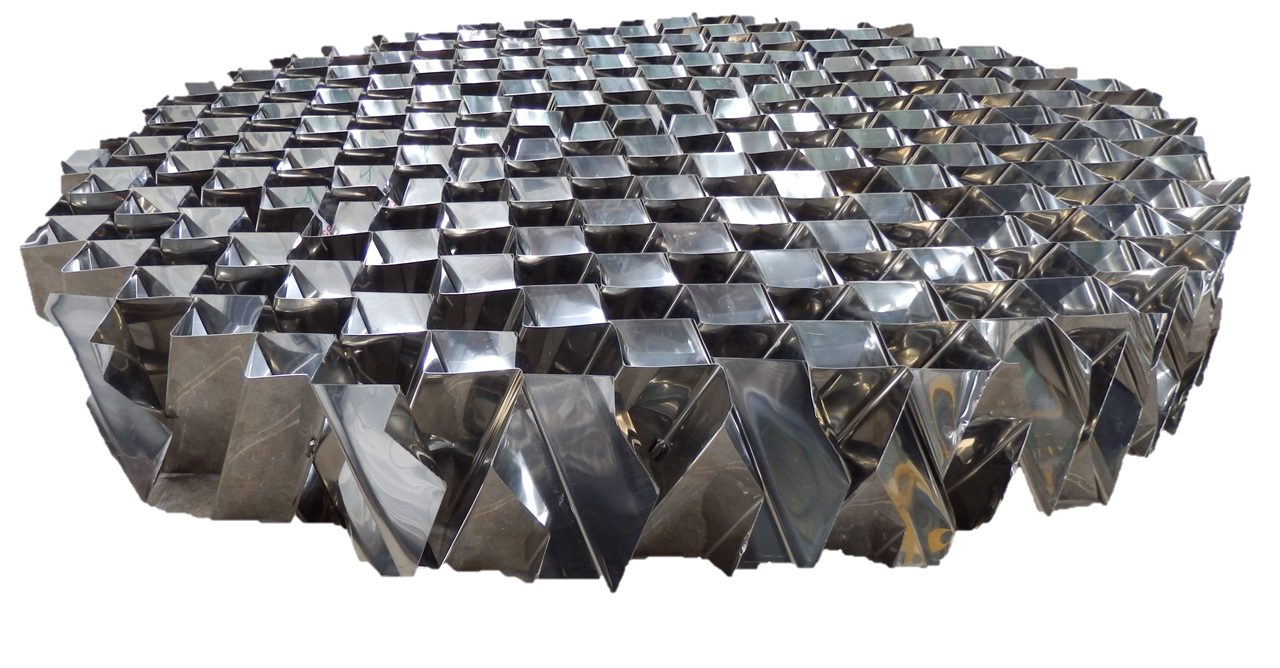

Products for the Pharmacutical industry

Case studies within Pharmaceutical industry

More on humidity control in pharmaceutical applications

Avoid unplanned production stops in your manufacturing process

In pharmaceutical and nutraceutical production, as well as in laboratories, an unplanned production stop can cause severe damage to the product quality or test results, and be very costly.

Munters equipment is always backed by our world-leading service team. They are directly employed by Munters, with decades of experience in maintaining our climate control systems for the pharmaceutical industry. With a Munters Service Agreement you can extend your dehumidification system's life, increase efficiency, minimize downtime, and ensure your production facilities will always stay regulatory compliant.