Make quality confectionery products

Hardy candy, biscuits, chocolate, jelly products, sugar-coated drops and popcorn lose quality and shelf life when exposed to excessive humidity. But you can make more high-quality confectionary products while reducing your carbon footprint by adding Munters dehumidification to your process.

- bullet

test

Tab Container Block TEST

Left column content

Left column content.

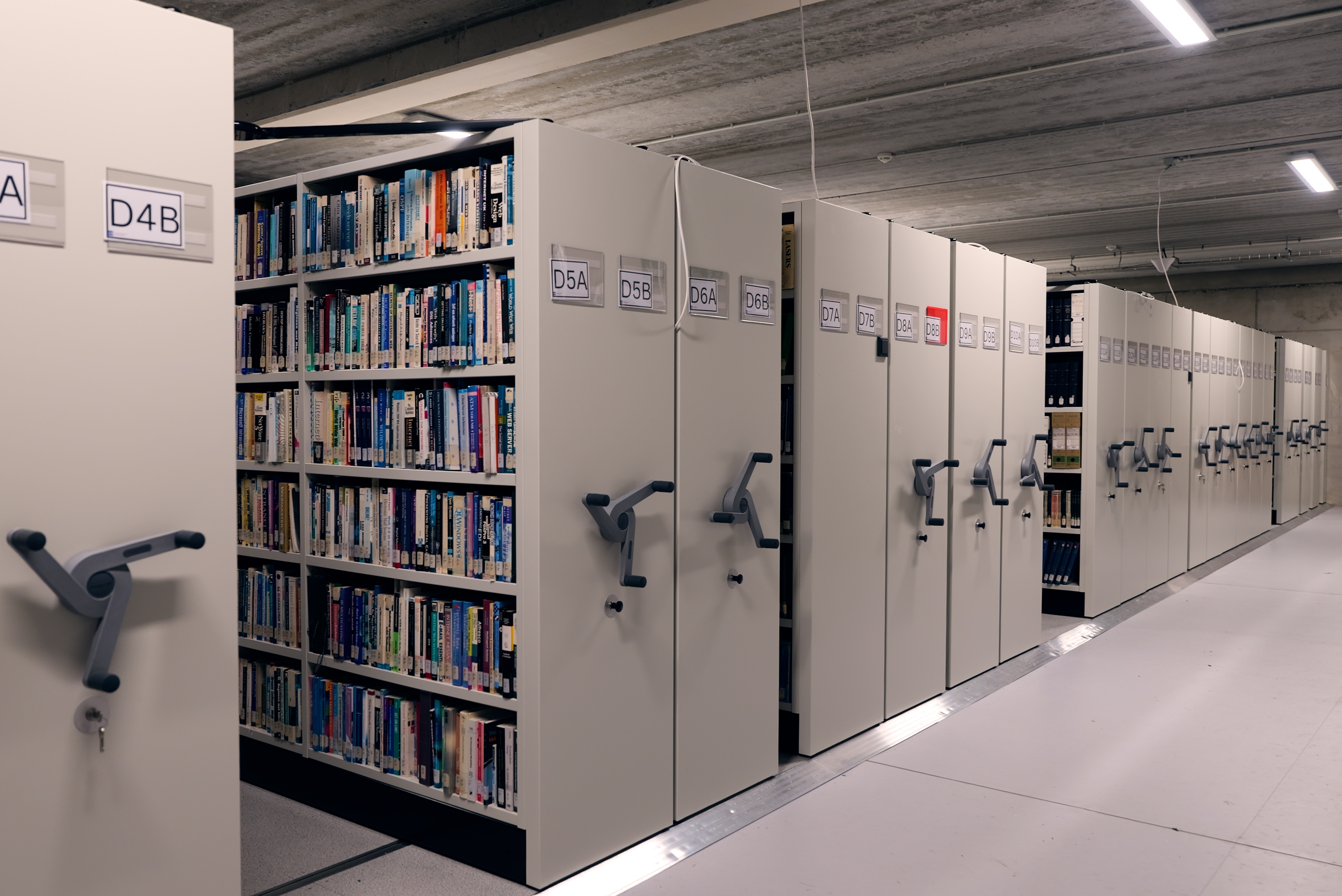

Munters Services maximize equipment lifespan

The Munters Service team is here to support you throughout the entire lifecycle of your equipment. Our experienced technicians can show you how to prevent unplanned downtime, lost production, compromised product quality, excessive energy consumption and unexpected costs. We help you protect your investment, your equipment and, most of all, your peace of mind.

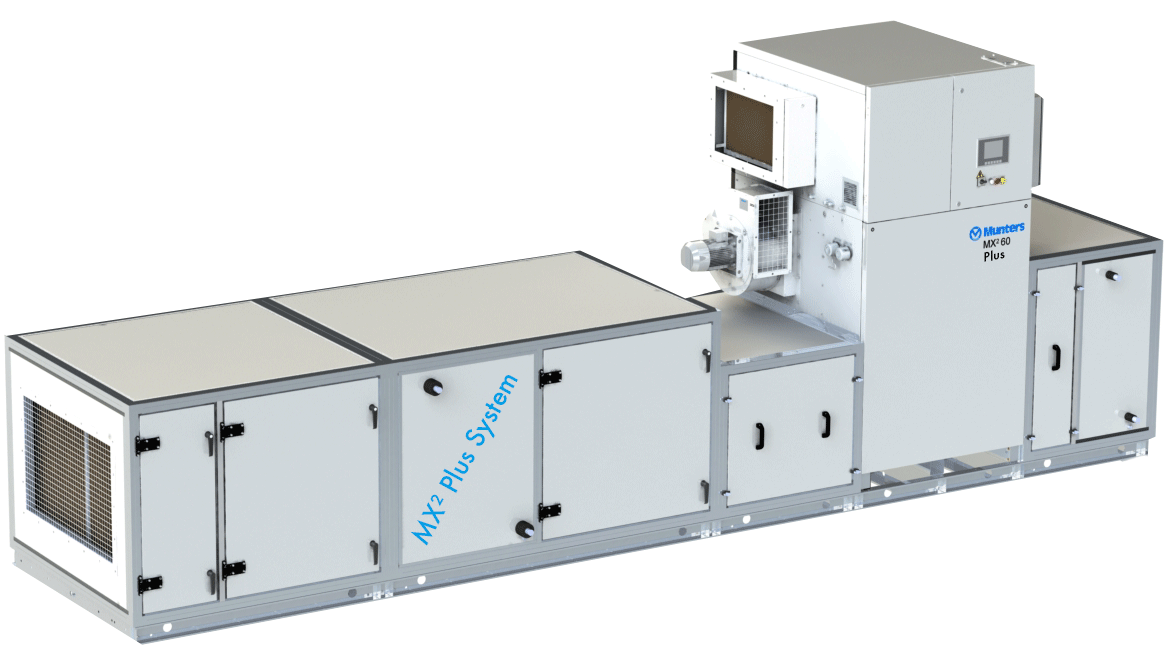

Data center products (Placeholder)

Installation, start-up and commissioning services for you

For dehumidification equipment

Our service technicians work with you from day one to get your equipment up and running to design specifications.

Learn more about how we can support you through the process of installation, start-up and commissioning

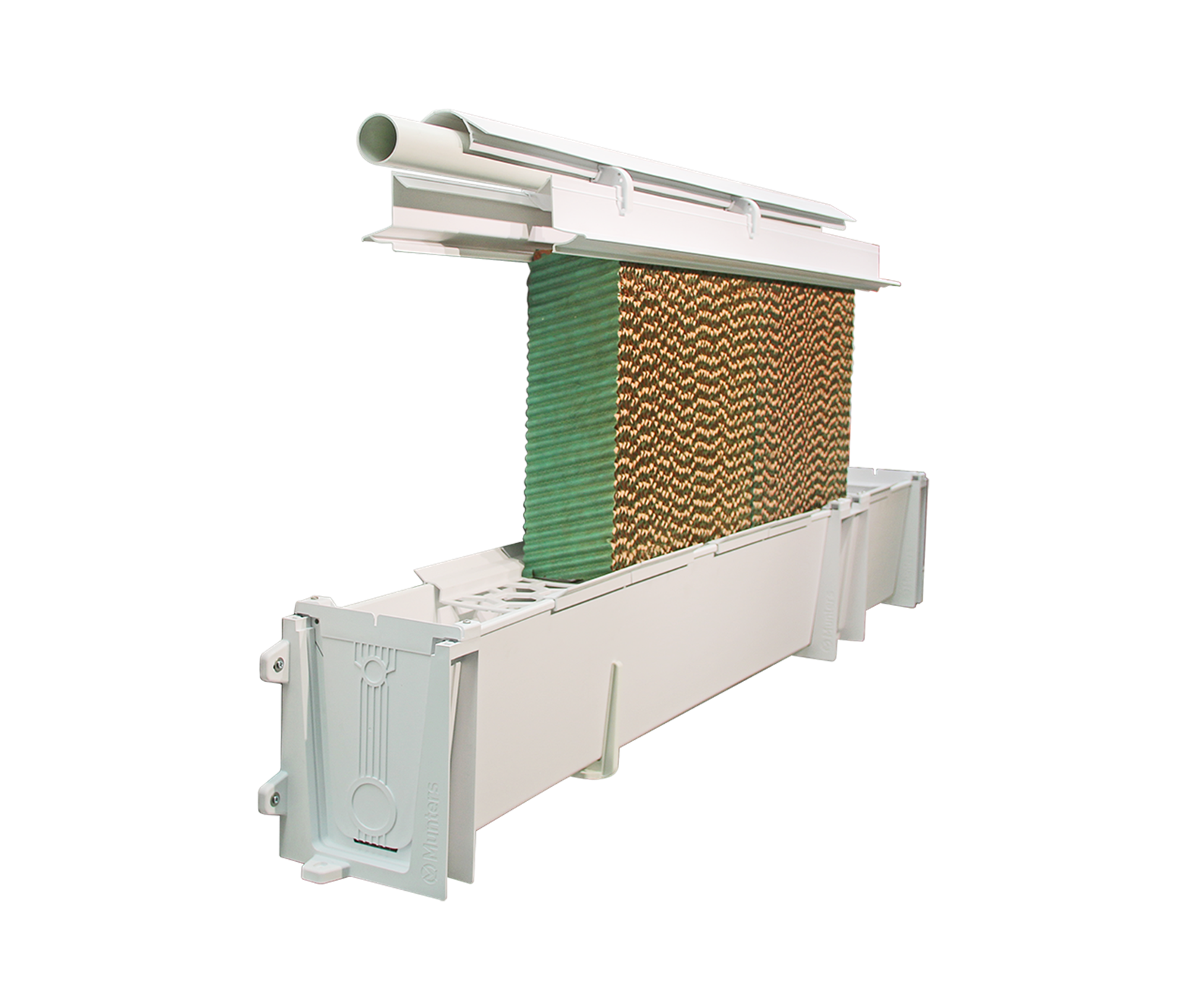

For mist elimination, mass transfer and VOC abatement equipment

Correct installation and start-up are essential to optimizing the performance of Munters mist elimination, mass transfer and VOC abatement equipment.

Learn more about how we can help

For data center products

To ensure optimal performance from day one, we offer start-up, installation supervision and commissioning support services for our datacenter air-cooling solutions.

Learn more about how we can help

For pig, poultry, dairy and greenhouse

We provide comprehensive services to get your new pig, poultry, dairy, or greenhouse operational. Our experienced technicians will ensure a smooth transition and proper operation of your system.

Munters helps you achieve:

Tab container block

Left column content.

Left column content.

- Bullet 1

- Bullet 2

Test

Test