Avfuktare för torra batterirum skapar en perfekt miljö för produktion av litiumjonbatterier

Oavsett om ni har ett litet FoU-labb, en mikromiljö eller en storskalig produktionsanläggning kan ni uppnå optimal fuktreglering och maximera produktionen av litiumjonbatterier med Munters lösningar för avfuktare för torrum.

För batteritillverkning i optimal miljö

Efterfrågan på litiumjonbatterier ökar hela tiden. De behövs i allt från hybridbilar och elbilar till mobiltelefoner, bärbara datorer och medicinsk utrustning. Batteritillverkarna har press på sig att öka tillgången samtidigt som de måste utveckla batterier med högre lagringskapacitet, längre livslängd och snabbare laddtid.

Fuktkontroll med låg daggpunkt i torra batterirum är avgörande vid tillverkning av litiumjonbatterier. Det garanterar en säker arbetsmiljö, hög drifttid och maximal tillverkningskvalitet. Munters avfuktare för torrum ger en effektiv och stabil luftfuktighetskontroll som säkerställer stabila prestanda året om. De är den perfekta lösningen för tillverkning av litiumjonbatterier då de uppnår daggpunkter på -40 °C till -70 °C eller ännu lägre, och minskar energiförbrukningen med upp till 30 %.

Resurser

Calculate the profit for your dry room

Calculate your energy savings with Munters dehumidifiers and download your personalized report.

The manufacturing of lithium-ion batteries takes place in extremely low humidity dry rooms where achieving and mantaining the right climate is essential in order to guarantee optimal product quality.

This calculator will help you design your dry room, and will show you the most important parameters to consider when looking to improve operational efficiency.

Optimal dehumidification is vital to lithium-ion battery manufacturing

Lithium is highly reactive to moisture, so battery production must occur in ultra-low humidity dry rooms. These super-dry conditions help secure product quality and worker safety. Achieving the correct dew point is essential. Not ensuring the proper dew point in your dry room can impact battery production.

- Production issues – unexpected downtime, leading to product loss and high costs.

- Product integrity – reduced battery quality, performance levels and yield.

- Increased operating costs – less efficient dehumidifiers use more energy and generate more carbon emissions over the lifespan of the dry room.

- Increased waste – more frequent quality issues and discarding faulty batteries adversely impacts the environment and your bottom line.

Optimera batteriproduktionen

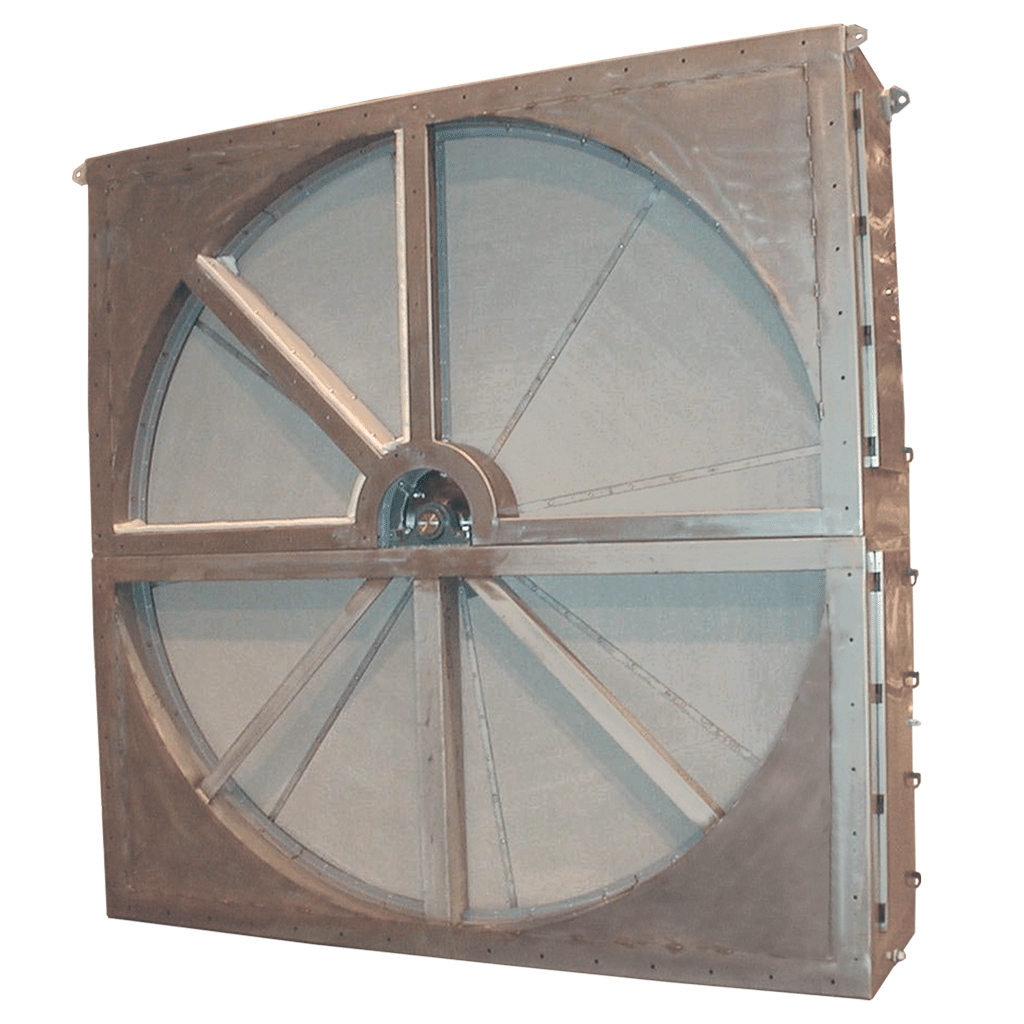

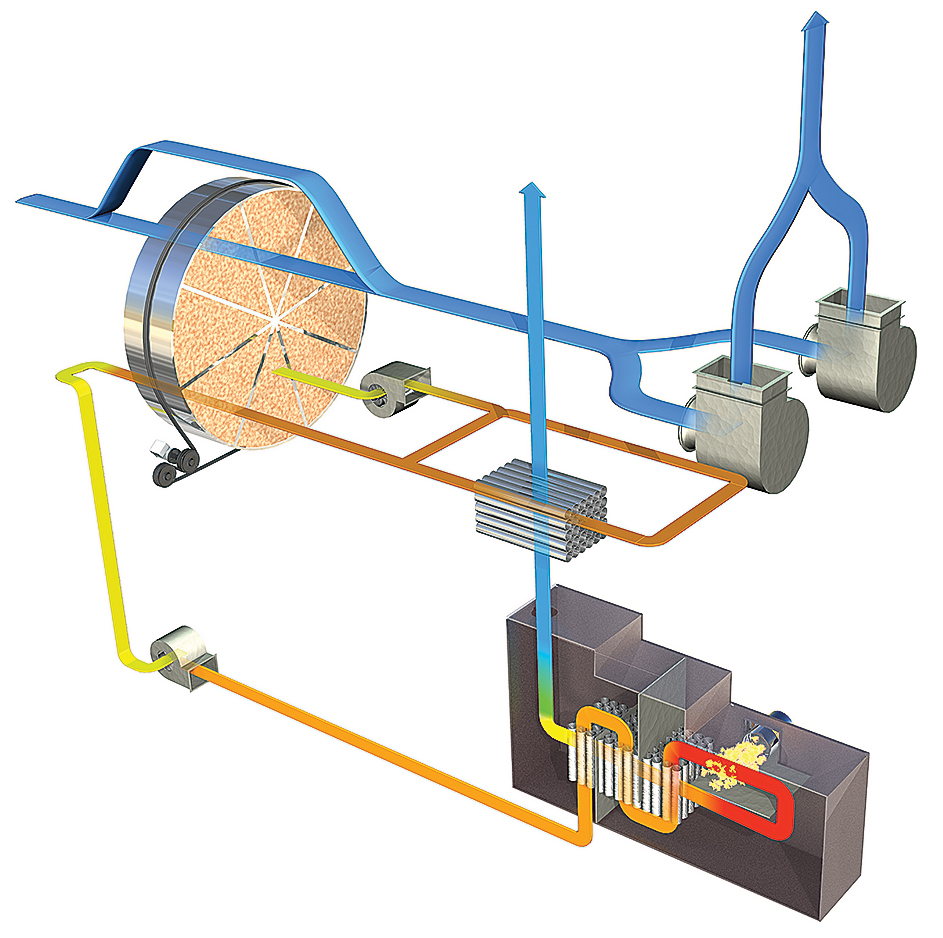

Avfuktningssystem med sorptionsrotor skapar en idealisk torrumsmiljö för batteritillverkning. Munters var pionjärer inom utvecklingen av tekniken för sorptionsavfuktare. Litiumjontillverkare världen över använder våra innovativa lösningar för att upprätthålla optimala klimatförhållanden och långvarig prestanda samtidigt som de sparar energi.

De flesta tillverkare måste upprätthålla en relativ luftfuktighet i torrummet som är så låg som <1 % eller daggpunkt på -40 °C, vilket motsvarar cirka 0,08 g/kg eller gram per kilo torr luft. Utveckling av nya batterikemikalier kan ytterligare sänka industristandarderna. Munters har tillhandahållit utrustning till torrum för produktion av litiumjonbatterier som levererar tilluft vid -89 °C, och vi fortsätter att förfina vår avfuktarteknik för att möta framtida krav.

Innovativa funktioner, som vår patenterade Munters Green PowerPurge-teknik, gör att våra litiumjonbatterilösningar kan uppnå högre genomströmning, lägre daggpunkt för lufttillförseln och upp till 30 % energibesparingar. Munters kompakta avfuktningssystem uppfyller era unika krav med mindre klimatavtryck än andra system. Det innebär att systemets totala ägandekostnad minskar.

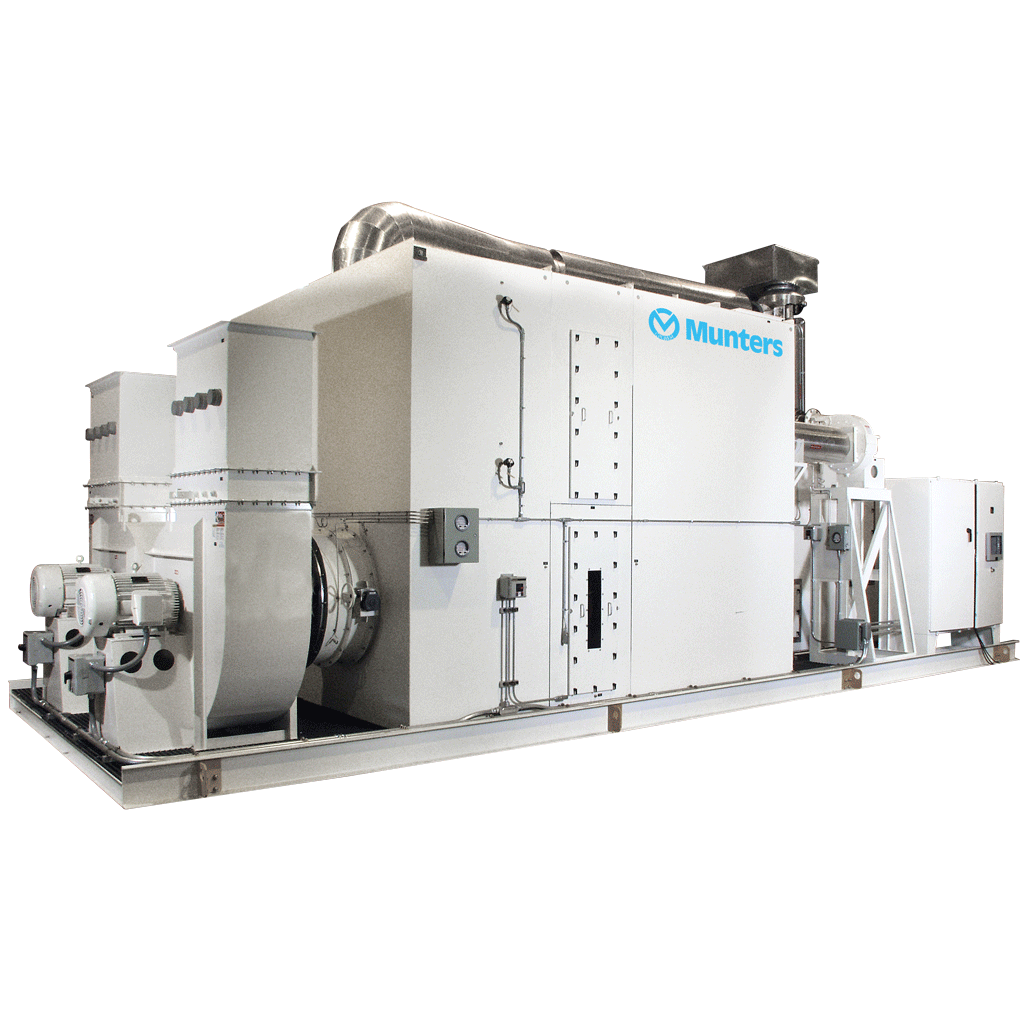

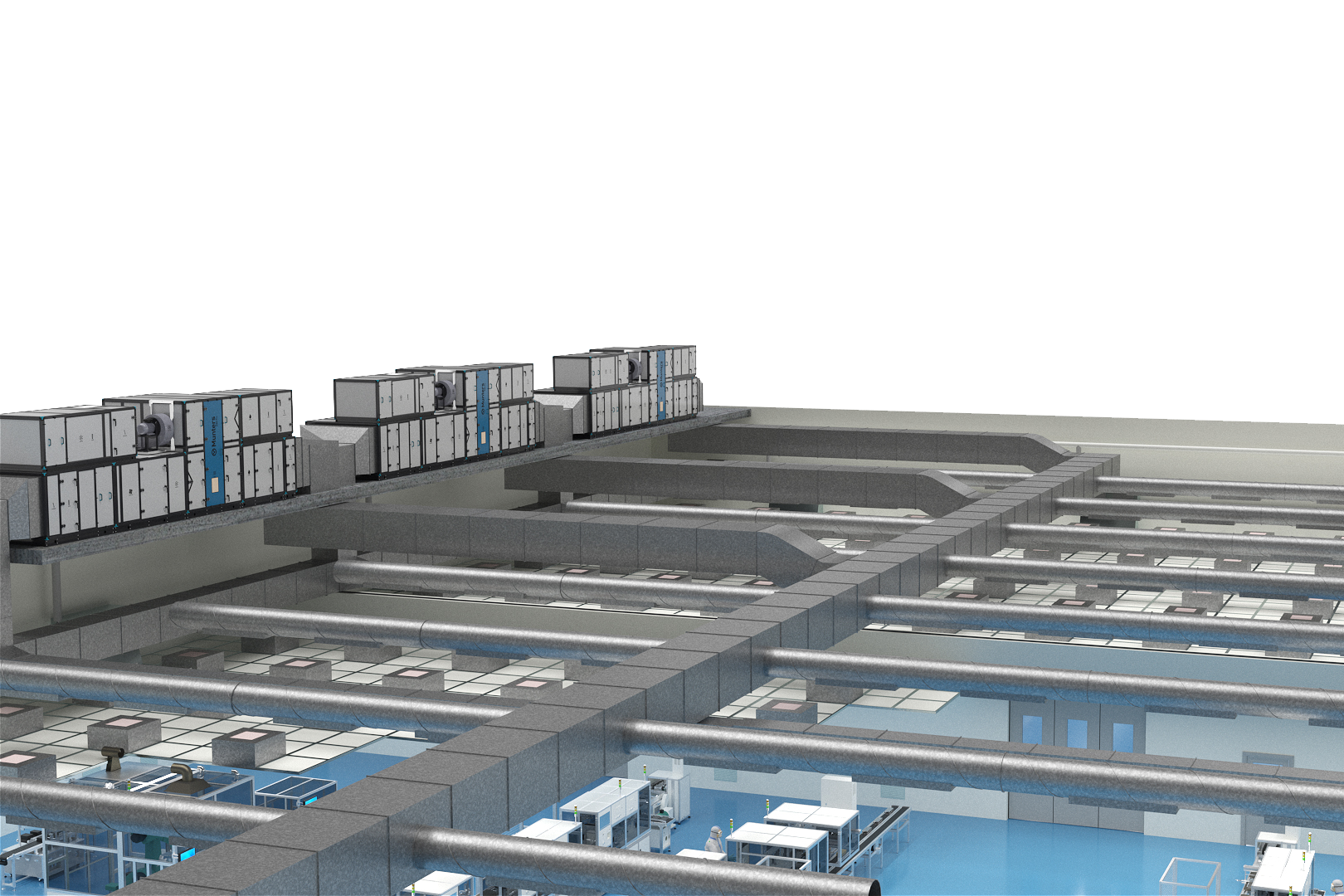

Bild: Munters DSS Pro-installation i en batteriproduktionsanläggning.

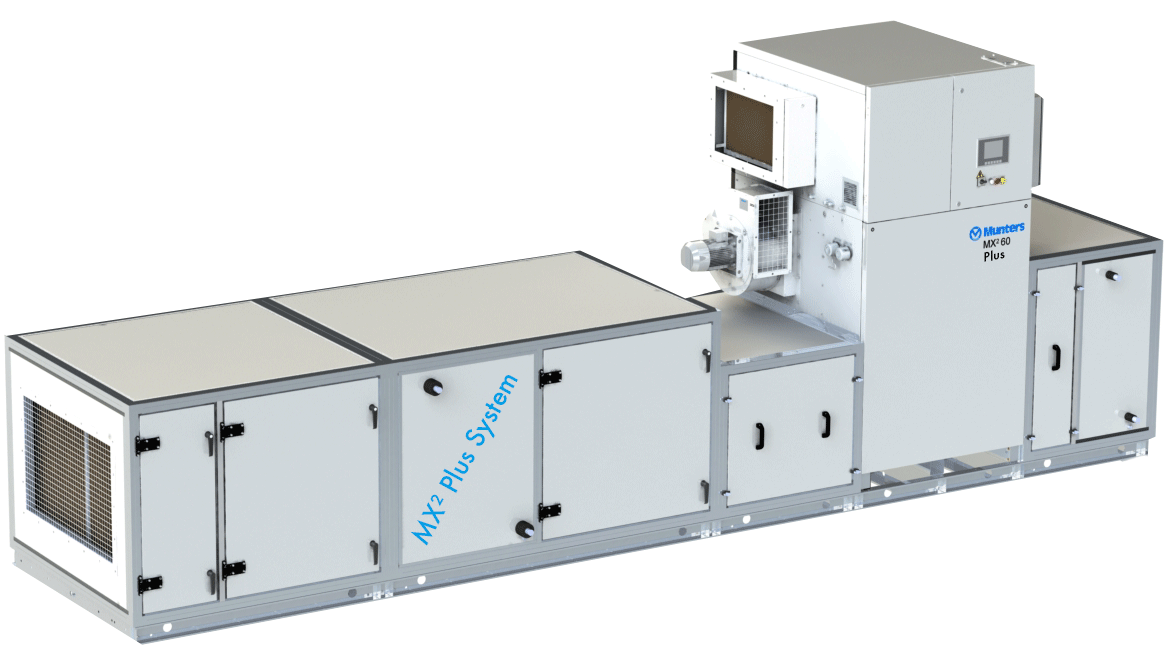

The right solution for your needs

Munters lithium-ion battery solutions are tailored to your needs. Depending on customer requirements, Munters can provide the following:

- Individual systems. Many of our individual products are key systems in the modern dry room.

- Micro-environments. Our compact bespoke solutions help minimize CAPEX and OPEX.

- Installed solutions. For customers who may not need a turnkey dry room solution but can benefit from Munters applications expertise, Munters provides system installation, ductwork and pipework to real-time humidity control.

- Turnkey solutions. Given our expertise and world-class technology, Munters provides turnkey dry room solutions. This gives the customer an excellent environment for lithium-ion battery production from a single dedicated partner.

Why choose Munters’ dry room solutions for lithium-ion battery production

Operating expenditures are likely to exceed capital expenditures, so it is vital to consider the total cost of ownership of the dry room over its entire service life.

Realizing up to 30% in annual energy savings can boost your bottom line with a fast return on investment and lower total cost of ownership.

What you get with Munters

- World leader in humidity control with more than 65 years of experience

- More than 3,000 low dew point dehumidifiers in use worldwide

- Dedicated project engineers optimize the design process recommending the right solution for your specific application

- Global footprint with ISO 9001-certified factories strategically located in Europe, the U.S. and China

- Easily achieves supply dew points of -70°F [-57°C] and below

- Improved cooling through energy optimization

- Up to 45% in reactivation energy savings compared to conventional systems

Meet the experts!

Our Battery Center of Excellence team as an international hub of expertise, talent and collective knowledge where we streamline best practices and ensures that we deliver cutting-edge technology to all our customers for manufacturing batteries in the most sustainable way.

We always look for waste heat to be integrated in our energy concept and we work on improving energy efficiency by development of new desiccant material and ultra-low dew point designs and by collecting live data on system performance and on energy use to refine our control software for more efficient and sustainable operations. We have set clear standards for operational excellence in our strategically located factories in Europe, US and China, and our service technicians have decades of knowledge and expertise commissioning battery rooms and integrating climate solutions.

Hear our experts sharing their view on innovation, value-based engineering, operational excellence, energy conservation and service.

Vill du veta hur ni kan hålla torrummet perfekt för produktionen?

Munters avfuktningslösningar upprätthåller luftfuktighet med låg daggpunkt och säkerställer stabila prestanda året runt, vilket säkerställer kvaliteten på litiumjonbatteritillverkningen.

Applications for battery

Electric vehicles

Electric vehicles are becoming more popular every day. Countries are looking at reducing vehicle-related emissions; some plan to ban the sale of new cars equipped with combustion engines. As a result, battery manufacturers must increase their capacity and capability, to accelerate lithium-ion battery production.

Consumer electronics

Mobile phones, computers and handheld devices continue to drive demand for lithium-ion batteries. Manufacturing lithium-ion batteries requires extremely low humidity levels to to ensure maximum quality, uptime and safe workspaces. Dew points as low as -40°F [-40°C] or even lower are a must for these extreme applications.

Lithium-ion batteries will play a crucial role in supporting energy storage systems for balancing power generation, storing excess energy in off-peak hours and enhancing the reliability of renewable energy sources. The demand for lithium-ion batteries for energy storage is growing rapidly worldwide.

Products - Battery

Rätt klimat för tillverkning av litiumjonbatterier

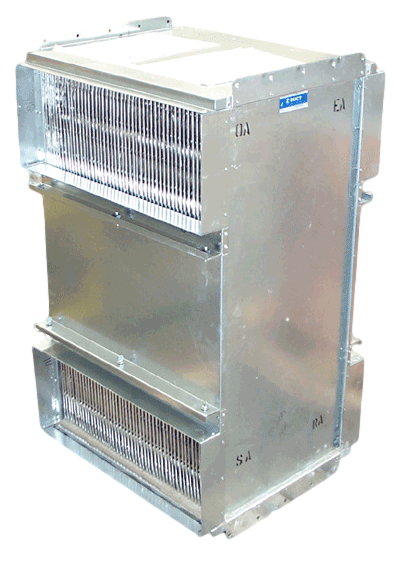

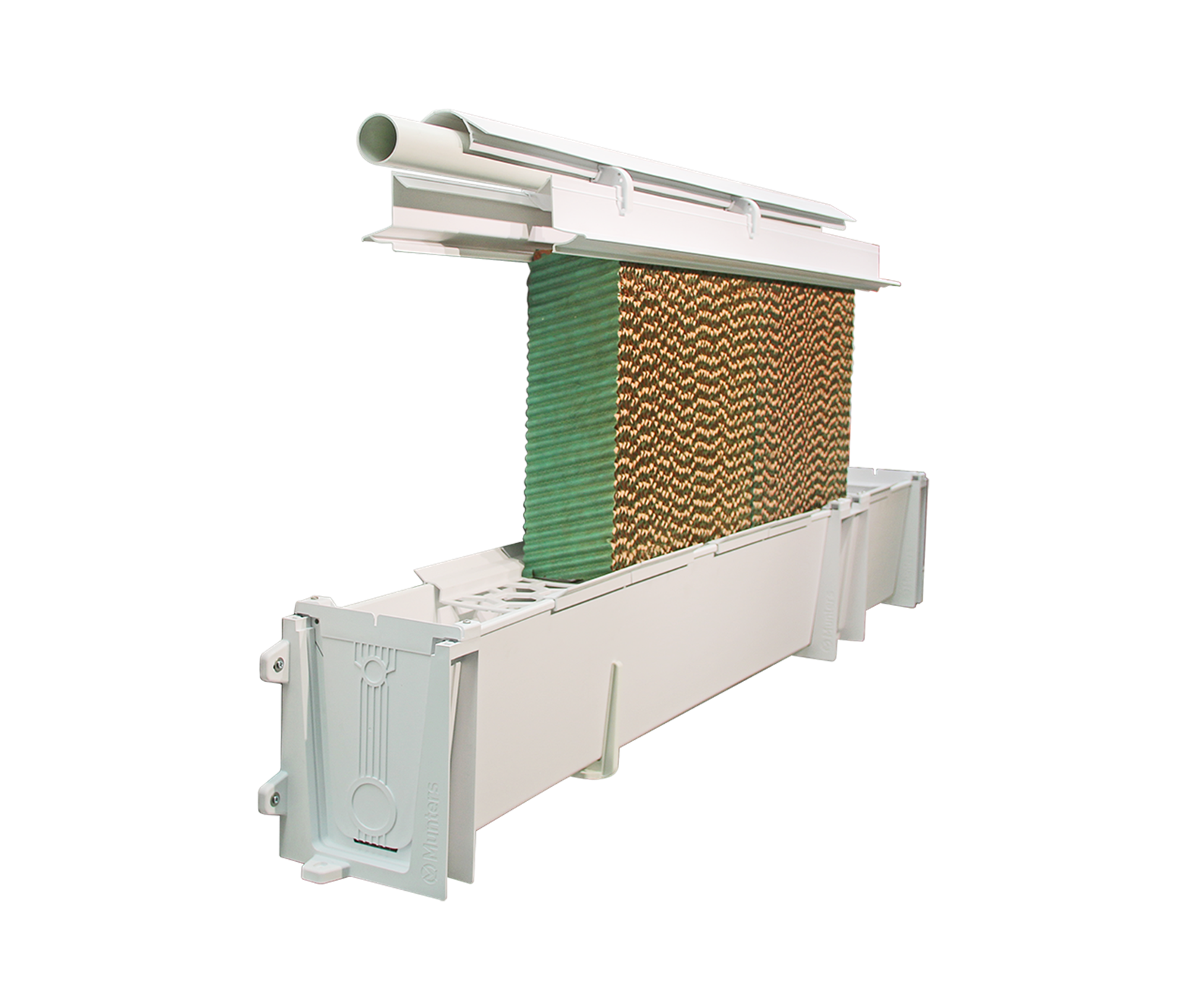

Munters DSS ger hög drifttid och extrem tillförlitlighet. Den är utformad för att hålla ett optimalt klimat med långvarig prestanda, samtidigt som den sparar energi.

Säkra process- och produktionskvaliteten med Munters DSS Pro.

“I selected Munters due to their historical experience in providing low dewpoint solutions within battery applications.”

Paul Blackmore, Project Manager

WMG’s Energy Innovation Centre

Munters services for lithium-ion battery optimization

Munters specializes in maximizing lithium-ion battery manufacturing efficiency with dry room dehumidification solutions that help achieve low dew points, reduced energy costs, and enhanced throughput. Safeguard your investment and minimize downtime with Munters Service Agreements and warranties. Take advantage of our comprehensive range of service offerings, including start-up and commissioning, extended warranty coverage, spare parts availability, and upgrade options, to optimize the performance and longevity of your lithium-ion battery dry room dehumidification system.

Get support for your lithium-ion battery systems

Partner with Munters for personalized support throughout your lithium-ion battery dry room climate control project. Utilize our industry-leading experience to select the optimal dehumidification solution. Whether you require start-up or commissioning support, warranty coverage, or spare parts, our proactive approach ensures peak efficiency and minimal interruptions. Trust Munters to deliver exceptional results for your lithium-ion battery dehumidification equipment, with dedicated service tailored to your specific needs and requirements.